Manufacturing

Facilities

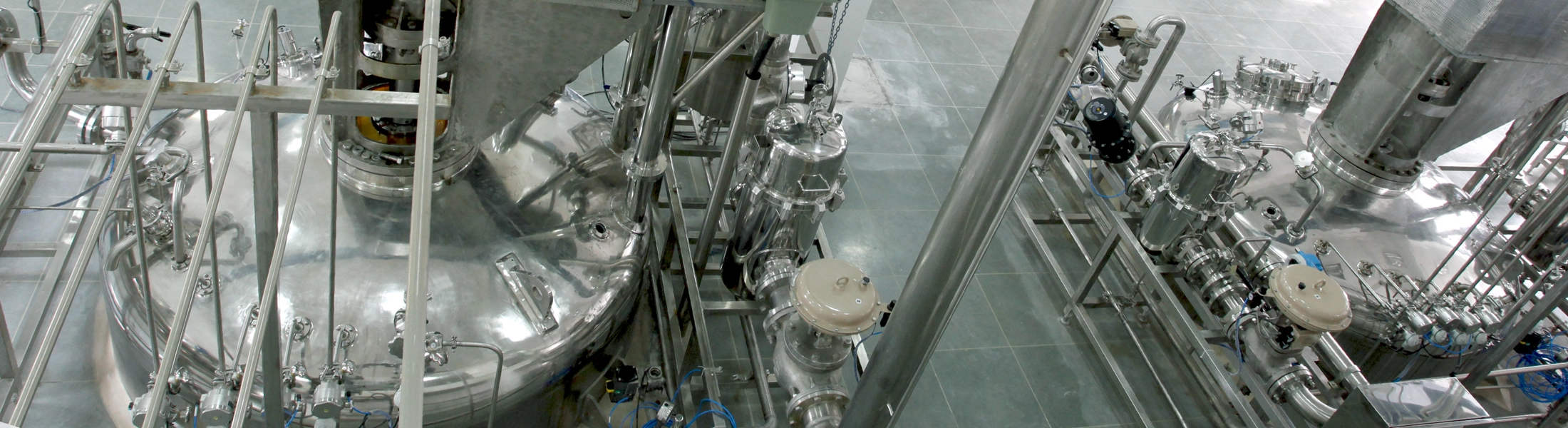

We have two operational industrial scale active pharmaceutical ingredients ("API") manufacturing facilities

We have established fully integrated, scale manufacturing infrastructure that supports both our own product development and our CDMO operations

- Rau, Mhow, Indore (Rau Facility)

- Pithampur Special Economic Zone, Madhya Pradesh (SEZ Facility)

Rau Facility

Commissioned in 2004, Houses Sterile and Non-Sterile Corticosteroid API manufacturing blocks The facility supports batch sizes ranging from small scale production of a few kilograms ("kgs") to over 250 kgs per batch for several APIs, with maximum capacity of 92 MT

US FDA, WHO-GMP, and EU-GMP (by Regierung von Oberbayern, Germany) and other regulatory authorities

Key Equipment/Technology

- Aseptic filling

- Pure steam generator / Steam sterilizer

- Lyophilizer with CIP and SIP features

- Class 100 environment

- Water for injection

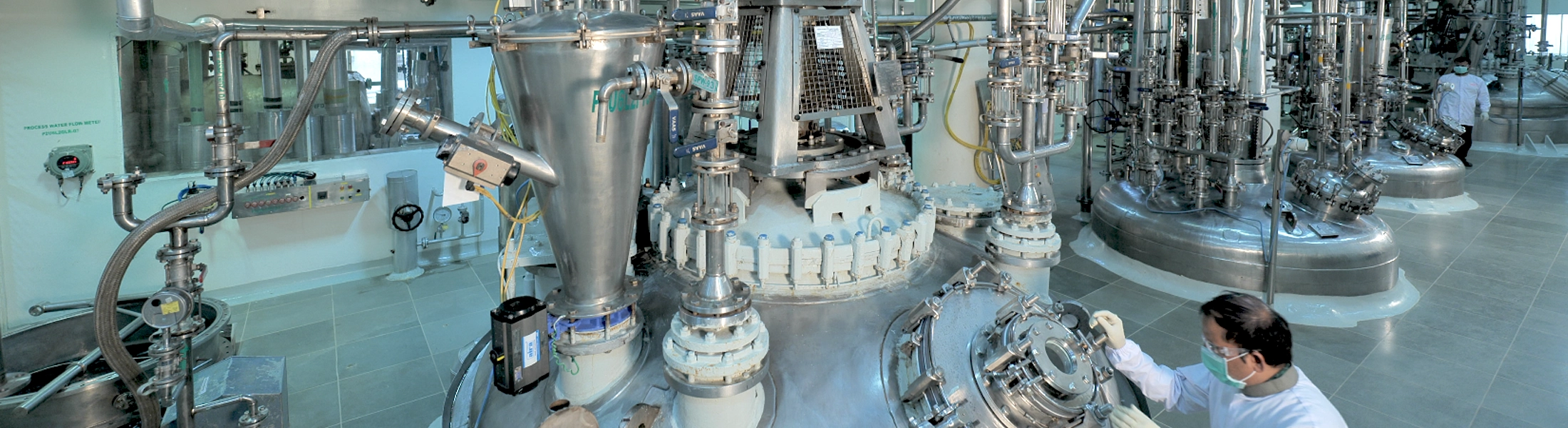

Pithampur Facility

Commissioned in 2009, Houses dedicated and isolated Steroid Hormone manufacturing blocks, Chemical Synthesis blocks, and Fermentation and Biotransformation blocks

US FDA, WHO-GMP, and EU-GMP (by Regierung von Oberbayern, Germany) and other regulatory authorities

Key Equipment/Technology

- Glass line reactors and stainless steel reactors

- Containment technology using enclosed powder transfer systems

- Glove box

- Electrodeionization US/Europe Pharmacopeia grade water

Core Competencies

What’s New

(Newly Commissioned

Facilities)

Biomanufacturing Facility – Ujjain

Commissioned 400 KL Biomanufacturing Facility has commenced for R&D and Pilot-Scale Operations

- Equipped with four High-volume Fermenters of 100 KL each

- Expansion underway for GLP-1 and Insulin demand

Complex Injectables Facilities – Mhow

Specializes in Complex Injectable manufacturing featuring Sterile environments and aseptic fill-finish

- Capacity: 20 million DCVs per annum

- Advanced Contamination Control Systems